Tech

Choosing the Right Conveyor Roller for Your Needs

Selecting the right conveyor roller is crucial for ensuring the efficiency and longevity of a conveyor system. The appropriate roller type can significantly impact the smooth transportation of materials, reduce maintenance costs, and enhance overall productivity. Conveyor rollers come in various types, each designed to meet specific industrial needs. These include steel rollers for heavy-duty applications, rubber-coated rollers for improved grip and noise reduction, and nylon rollers known for their durability and corrosion resistance. Understanding the unique features and benefits of each type helps in making informed decisions, tailored to the demands of different operational environments.

Conveyor Roller Types

Conveyor rollers are an essential component in many types of conveyor systems, facilitating the movement of products and materials along the conveyor path. The design, material, and application of the rollers can significantly impact the efficiency and effectiveness of the conveyor system. Below, we delve into the various types of conveyor rollers, highlighting their specific characteristics, uses, and benefits.

Gravity Rollers

Gravity rollers are the simplest form of conveyor rollers. They do not require any external power to function, relying solely on gravity to move items along the conveyor path. These rollers are commonly used in warehouses and distribution centers where the transportation of goods can be done manually or by the natural slope of the conveyor system.

Key Characteristics:

Material: Typically made from steel or aluminum.

Cost-effective: Low initial and maintenance costs.

Durability: Suitable for handling medium to heavy loads.

Applications:

– Packaging lines

– Assembly lines

– Order picking and fulfillment areas

Powered Rollers

Powered rollers, also known as live rollers, are driven by motors and can transport products automatically. These rollers are ideal for applications requiring precise control over the movement of items.

Key Characteristics:

Material: Usually made from steel, but can also be coated with rubber or plastic for specific applications.

Variable Speed: Can be adjusted to control the speed of the conveyor.

Efficiency: High throughput capabilities.

Applications:

– Manufacturing lines

– Distribution centers

– Automated sorting systems

Plastic Rollers

Plastic rollers are lightweight and corrosion-resistant, making them suitable for specific environments where traditional metal rollers might not perform well.

Key Characteristics:

Material: High-quality plastic such as polypropylene or nylon.

Lightweight: Easier to handle and install.

Corrosion-resistant: Ideal for use in wet or corrosive environments.

Applications:

– Food processing

– Chemical manufacturing

– Cleanrooms

Stainless Steel Rollers

Stainless steel rollers are known for their durability and resistance to corrosion, making them ideal for heavy-duty applications and harsh environments.

Key Characteristics:

Material: High-grade stainless steel.

Durable: Can withstand heavy loads and harsh conditions.

Hygienic: Easy to clean and maintain.

Applications:

– Pharmaceutical manufacturing

– Food and beverage industry

– Outdoor conveyor systems

Rubber-Coated Rollers

Rubber-coated rollers provide additional grip and cushioning, making them suitable for handling delicate or fragile items.

Key Characteristics:

Material: Steel core with a rubber or urethane coating.

Shock Absorption: Reduces damage to products during transportation.

Traction: Improved grip on items.

Applications:

– Glass and ceramics transport

– Electronics manufacturing

– Textile industry

Conical Rollers

Conical rollers are used in curved sections of conveyor systems, allowing for smooth and consistent movement around bends.

Key Characteristics:

Material: Can be made from steel, aluminum, or plastic.

Tapered Design: Facilitates smooth navigation around curves.

Customizable: Available in various sizes and taper angles.

Applications:

– Airport baggage handling

– Parcel sorting facilities

– Manufacturing plants with curved conveyor lines

Polyurethane Rollers

Polyurethane rollers are designed for applications requiring a combination of durability, chemical resistance, and noise reduction.

Key Characteristics:

Material: Polyurethane-coated steel or aluminum core.

Chemical Resistance: Suitable for use in environments with exposure to oils, solvents, and other chemicals.

Quiet Operation: Reduces noise during conveyor operation.

Applications:

– Automotive industry

– Heavy equipment manufacturing

– Aerospace industry

Conveyor Impact Rollers

Conveyor impact rollers are reinforced to absorb shock and prevent damage to both the conveyor system and the materials being transported.

Key Characteristics:

Material: Steel or rubber-coated steel.

Shock Absorption: Designed to handle high-impact areas.

Durability: Long-lasting even under extreme conditions.

Applications:

– Mining operations

– Bulk material handling

– Quarry conveyor systems

Choosing the right type of conveyor roller is crucial for optimizing the efficiency and longevity of a conveyor system. Each type of roller offers unique benefits tailored to specific applications and environments. By understanding the characteristics and applications of each roller type, businesses can select the best solutions to meet their operational needs.

Best Nylon Conveyor Rollers

Nylon conveyor rollers are a popular choice in many industries due to their unique blend of strength, durability, and lightweight properties. They are particularly valued for their resistance to wear and corrosion, making them suitable for a wide range of applications. In this section, we will explore the characteristics of high-quality nylon rollers and provide recommendations on some of the best products and brands in the market.

Characteristics of High-Quality Nylon Rollers

Understanding the key characteristics of high-quality nylon rollers can help in selecting the best products for your needs. Below are some essential features to consider:

Material Composition

High-quality nylon rollers are made from premium nylon materials that offer excellent mechanical properties. The best rollers often use high-density nylon, which provides superior strength and durability.

High-Density Nylon: Offers better load-bearing capacity and wear resistance.

Additives: Some nylon rollers are enhanced with additives to improve specific properties, such as UV resistance or anti-static capabilities.

Durability and Wear Resistance

Nylon rollers are known for their long lifespan and ability to withstand harsh environments. They exhibit excellent wear resistance, which is crucial for maintaining performance over time.

Wear Resistance: Ensures longevity and reduces maintenance costs.

Impact Resistance: Can handle shocks and impacts without cracking or deforming.

Lightweight

One of the main advantages of nylon rollers is their lightweight nature. This makes them easier to install and reduces the overall weight of the conveyor system, which can be beneficial for certain applications.

Ease of Installation: Simplifies the assembly process.

Energy Efficiency: Reduces the energy required to drive the conveyor system.

Corrosion Resistance

Nylon rollers are highly resistant to corrosion, making them ideal for use in environments where they might be exposed to chemicals, moisture, or other corrosive substances.

Chemical Resistance: Suitable for chemical manufacturing and food processing.

Moisture Resistance: Prevents degradation in humid or wet conditions.

Low Noise Operation

Nylon rollers operate quietly, which is an essential feature in environments where noise reduction is critical, such as in office buildings or hospitals.

Noise Reduction: Minimizes operational noise, contributing to a quieter working environment.

Recommended Products and Brands

Several brands and products stand out in the market for their superior quality and performance. Below are some of the best nylon conveyor rollers available:

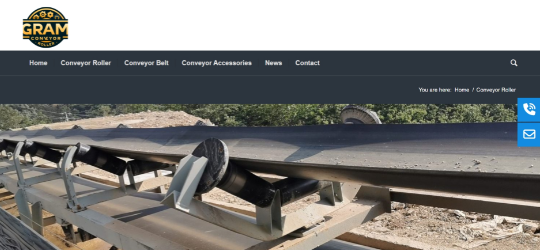

GRAM Conveyor

The GRAM Conveyor is renowned for its high-quality nylon material and exceptional performance. These rollers are designed for heavy-duty applications and offer a combination of durability, lightweight, and easy maintenance.

Key Features:

– High-grade nylon material for excellent strength and wear resistance.

– Lightweight design for easy installation and energy efficiency.

– Corrosion-resistant properties suitable for various industrial environments.

Applications:

– Mining operations

– Manufacturing plants

Interroll – Polyamide Rollers

Interroll is a well-known name in the conveyor industry, and their polyamide rollers are among the best in the market. These rollers are made from high-quality polyamide, a type of nylon known for its robust performance and versatility.

Key Features:

– High load-bearing capacity.

– Excellent wear and impact resistance.

– Low friction and noise levels.

Applications:

– Material handling

– Distribution centers

– Packaging lines

Dyno – Nylon Rollers

Dyno offers a range of nylon rollers designed for various industrial applications. Their rollers are appreciated for their durability and efficiency, making them a reliable choice for demanding environments.

Key Features:

– Made from high-density nylon for enhanced durability.

– Corrosion-resistant and suitable for wet environments.

– Lightweight and easy to install.

Applications:

– Mining operations

– Manufacturing plants

– Warehouses

Conveyor Units – Nylon Conveyor Rollers

Conveyor Units provides high-quality nylon conveyor rollers known for their resilience and long service life. These rollers are designed to handle a wide range of materials and operating conditions.

Key Features:

– Premium nylon construction for superior strength and wear resistance.

– Smooth and quiet operation.

– Resistant to chemical and environmental corrosion.

Applications:

– Airport baggage handling

– Automotive industry

– Pharmaceutical manufacturing

Selecting the best nylon conveyor rollers involves considering factors such as material composition, durability, weight, corrosion resistance, and noise levels. The recommended products and brands listed above are known for their high quality and performance, making them suitable for various industrial applications. By choosing the right nylon rollers, businesses can ensure efficient and reliable operation of their conveyor systems, leading to improved productivity and reduced maintenance costs.

Conveyor Roller with Bracket

Conveyor rollers with brackets are essential components in many conveyor systems. They provide the necessary support and stability for the rollers, ensuring efficient and smooth operation. In this section, we will discuss the importance and functionality of conveyor rollers with brackets, as well as explore the various types of brackets and their applications.

Importance and Functionality

1. Support and Stability

Brackets play a crucial role in supporting conveyor rollers, maintaining their alignment, and ensuring they remain securely in place. This support is vital for the smooth and efficient movement of goods along the conveyor system.

Proper Alignment: Brackets ensure that rollers are correctly aligned, preventing deviations that could disrupt the flow of materials.

Secure Attachment: They provide a stable and secure attachment point for rollers, minimizing the risk of dislodgement or misalignment.

2. Load Distribution

Brackets help distribute the load evenly across the conveyor rollers, reducing the stress on individual rollers and enhancing the overall durability of the system.

Even Load Bearing: Ensures that the load is evenly distributed, preventing excessive wear on any single roller.

Enhanced Durability: By reducing localized stress, brackets contribute to the longevity of the conveyor system.

3. Ease of Maintenance

Conveyor rollers with brackets are designed for easy installation and maintenance. This feature helps minimize downtime and ensures the conveyor system remains operational.

Quick Replacement: Brackets allow for the quick and easy replacement of rollers, reducing maintenance time.

Modular Design: Many brackets are part of modular systems, making it easier to maintain and upgrade conveyor components.

Types of Brackets and Their Applications

There are various types of brackets used in conveyor systems, each designed for specific applications and operational requirements. Below, we explore some common types of brackets and their typical uses.

1. Fixed Brackets

Fixed brackets are the most basic type of conveyor roller bracket. They hold the roller in a fixed position and are suitable for applications where the conveyor path is straight and does not require frequent adjustments.

Applications:

– Simple straight conveyor lines

– Warehousing and distribution centers

– Manufacturing assembly lines

2. Adjustable Brackets

Adjustable brackets allow for the positioning of conveyor rollers to be modified. This flexibility is beneficial in applications where the conveyor path may need to change or where different roller positions are required to accommodate various load sizes.

Applications:

– Customizable conveyor systems

– Flexible manufacturing processes

– Assembly lines with varying product sizes

3. Swivel Brackets

Swivel brackets enable the rollers to pivot or rotate, allowing for greater flexibility in handling materials. These brackets are ideal for applications that involve curved conveyor paths or where items need to be redirected smoothly.

Applications:

– Curved conveyor sections

– Sorting and redirecting systems

– Parcel handling and distribution

4. Hinged Brackets

Hinged brackets are designed to allow the rollers to be easily lifted or moved aside. This feature is particularly useful for cleaning, maintenance, and quick access to the conveyor belt.

Applications:

– Food processing and packaging

– Pharmaceutical manufacturing

– Conveyor systems requiring frequent cleaning and maintenance

5. Spring-loaded Brackets

Spring-loaded brackets provide a cushioning effect, allowing the roller to absorb shocks and impacts. This type of bracket is useful in applications where the conveyor system handles heavy or irregular loads.

Applications:

– Mining and quarrying

– Heavy-duty material handling

– Impact zones in conveyor systems

6. Custom Brackets

Custom brackets are designed to meet specific requirements of unique conveyor applications. These brackets can be tailored to fit unusual conveyor layouts, specialized roller types, or specific environmental conditions.

Applications:

– Specialized industrial processes

– Custom-built conveyor systems

– Environments with unique operational challenges

Conveyor rollers with brackets are essential for the efficient and reliable operation of conveyor systems. They provide critical support, stability, and load distribution, ensuring that rollers function optimally. The variety of bracket types available allows for customization to meet specific application needs, enhancing the versatility and adaptability of conveyor systems. By understanding the importance and functionality of different brackets, businesses can select the best solutions to improve their conveyor operations, leading to increased efficiency, reduced downtime, and lower maintenance costs.

Carrying Roller Conveyor Belt

A carrying roller conveyor belt is a fundamental component in the smooth operation of conveyor systems. These belts, supported by carrying rollers, are essential for transporting materials efficiently from one point to another. In this section, we will explore the role of carrying roller conveyor belts in conveyor systems, key features that make them effective, and maintenance tips to ensure their longevity and reliability.

Role in Conveyor Systems

1. Material Transportation

The primary role of carrying roller conveyor belts is to transport materials efficiently across different stages of processing or handling. These belts are widely used in various industries to move bulk materials, packages, or products from one location to another.

Continuous Movement: Ensures a steady flow of materials, reducing manual handling and increasing operational efficiency.

Versatility: Suitable for transporting a wide range of materials, including raw materials, finished products, and packaging.

2. Support and Stability

Carrying rollers provide crucial support to the conveyor belt, ensuring it remains stable and aligned during operation. This stability is vital for maintaining the integrity of the transported materials and the conveyor system itself.

Belt Alignment: Prevents the belt from sagging or misaligning, which can cause operational disruptions.

Load Distribution: Evenly distributes the weight of the transported materials, minimizing wear and tear on the belt.

3. Enhanced Efficiency

By providing a smooth and consistent surface for material movement, carrying roller conveyor belts enhance the overall efficiency of the conveyor system. They reduce friction and resistance, allowing for faster and more reliable transportation.

Reduced Energy Consumption: Lower friction means less energy is required to move the belt, leading to cost savings.

Increased Throughput: Facilitates faster movement of materials, boosting productivity.

Key Features

1. Durable Material

Carrying roller conveyor belts are made from durable materials that can withstand the rigors of industrial environments. The choice of material affects the belt’s performance, longevity, and suitability for specific applications.

Rubber: Commonly used for its flexibility, strength, and resistance to abrasion.

PVC: Offers good chemical resistance and is suitable for food-grade applications.

Polyurethane: Known for its excellent wear resistance and load-bearing capacity.

2. Robust Design

The design of carrying roller conveyor belts is tailored to handle the specific demands of the materials they transport. This includes considerations for load capacity, speed, and environmental conditions.

Reinforced Construction: Ensures the belt can handle heavy loads without stretching or deforming.

Impact Resistance: Designed to absorb shocks and impacts, protecting both the belt and the materials.

3. Customizability

Carrying roller conveyor belts can be customized to meet the specific needs of different industries and applications. Custom features might include specific belt widths, lengths, and surface textures.

Belt Width and Length: Customized to fit the dimensions of the conveyor system and the size of the transported materials.

Surface Texture: Can be smooth or textured to accommodate different types of materials and improve grip.

Maintenance Tips

1. Regular Inspection

Frequent inspection of the conveyor belt and carrying rollers is essential to identify any signs of wear, damage, or misalignment. Early detection of issues can prevent major breakdowns and extend the belt’s lifespan.

Visual Checks: Look for signs of wear, such as fraying edges or surface cracks.

Roller Alignment: Ensure carrying rollers are properly aligned and rotating smoothly.

2. Proper Lubrication

Lubricating the moving parts of the conveyor system, including the carrying rollers, reduces friction and wear. Use the appropriate lubricant recommended by the manufacturer to maintain optimal performance.

Scheduled Lubrication: Follow a regular lubrication schedule to ensure all moving parts operate smoothly.

Avoid Over-Lubrication: Excess lubricant can attract dust and debris, causing additional wear.

3. Belt Tensioning

Maintaining the correct tension in the conveyor belt is crucial for its efficient operation. An improperly tensioned belt can slip, cause misalignment, or suffer excessive wear.

Tension Adjustments: Regularly check and adjust the belt tension as needed to maintain optimal performance.

Avoid Over-Tensioning: Excessive tension can strain the belt and rollers, leading to premature failure.

4. Cleaning and Debris Removal

Keeping the conveyor belt and rollers clean is vital for preventing material buildup that can cause operational issues. Regular cleaning helps maintain the efficiency and longevity of the conveyor system.

Routine Cleaning: Clean the belt and rollers regularly to remove dirt, dust, and debris.

Preventative Measures: Implement measures to minimize debris accumulation, such as installing scrapers or guards.

Carrying roller conveyor belts are integral to the effective functioning of conveyor systems, providing essential support, stability, and efficiency in material transportation. By understanding their role, key features, and maintenance requirements, businesses can ensure these belts operate reliably and efficiently. Regular maintenance and proper care are crucial for maximizing the lifespan and performance of carrying roller conveyor belts, leading to enhanced productivity and reduced operational costs.

Impact Roller Compactor

An impact roller compactor is a powerful piece of machinery used in the construction and civil engineering industries to compact soil and other materials. This equipment is essential for creating stable and durable surfaces, whether for roads, foundations, or other infrastructure projects. In this section, we will delve into the purpose and usage of impact roller compactors, along with their key benefits and the industries they serve.

Purpose and Usage

1. Soil Compaction

The primary purpose of an impact roller compactor is to compact soil to increase its density and stability. This process is crucial for preparing construction sites, ensuring that the ground can support structures and withstand environmental stressors.

Achieving Desired Density: Ensures that the soil reaches the required density for stability and load-bearing capacity.

Reducing Settling: Compacted soil minimizes the risk of future settling, which can lead to structural damage.

2. Foundation Preparation

Impact roller compactors are extensively used in preparing foundations for buildings, roads, and other infrastructure. By compacting the ground, they create a solid base that can support heavy loads.

Uniform Compaction: Provides a consistent and even compaction across the entire foundation area.

Enhanced Load Bearing: Strengthens the foundation to support the weight of structures and traffic.

3. Road Construction

In road construction, impact roller compactors play a vital role in creating a stable and durable base layer. This layer is essential for the longevity and performance of the road.

Subgrade Compaction: Ensures that the subgrade is properly compacted to prevent road failures.

Improved Surface Quality: Leads to smoother and more durable road surfaces.

Key Benefits

1. Efficiency and Speed

Impact roller compactors are known for their efficiency and speed in compacting large areas of soil quickly. This capability significantly reduces the time required for site preparation and construction.

High Productivity: Can cover large areas rapidly, speeding up the compaction process.

Cost-effective: Reduces labor and time costs associated with soil compaction.

2. Deep Compaction

Unlike traditional compactors, impact roller compactors can achieve deep compaction, making them suitable for projects that require substantial soil stabilization.

Effective Depth: Can compact soil to greater depths, ensuring comprehensive ground stabilization.

Versatility: Suitable for various soil types and conditions.

3. Versatile Application

Impact roller compactors can be used in a wide range of applications, from small construction projects to large-scale infrastructure developments.

Adaptability: Can be used in different terrains and soil conditions.

Wide Range of Uses: Applicable in various stages of construction and civil engineering projects.

4. Reduced Environmental Impact

Modern impact roller compactors are designed to be environmentally friendly, reducing emissions and noise levels. This makes them suitable for use in urban areas and sensitive environments.

Low Emissions: Compliant with environmental regulations, reducing the carbon footprint.

Noise Reduction: Operate quietly, minimizing noise pollution in populated areas.

Industries Served

1. Construction

The construction industry heavily relies on impact roller compactors for site preparation, foundation work, and road building. Their ability to compact soil quickly and effectively makes them indispensable for constructing durable and stable structures.

Residential Construction: Preparing foundations for houses and residential complexes.

Commercial Construction: Compaction for commercial buildings and facilities.

2. Civil Engineering

Civil engineering projects, such as highways, bridges, and dams, require robust ground compaction to ensure structural integrity. Impact roller compactors are essential in achieving the required soil density for these projects.

Road and Highway Construction: Creating stable bases for roads and highways.

Bridge Foundations: Ensuring the ground can support heavy bridge structures.

3. Mining

In the mining industry, impact roller compactors are used to stabilize the ground for mining operations and to prepare sites for the construction of mining facilities.

Site Preparation: Compacting soil for mining infrastructure.

Tailings Management: Stabilizing tailings storage areas to prevent erosion and contamination.

4. Agriculture

Impact roller compactors also find use in agriculture for tasks such as preparing fields for planting and constructing farm roads. Proper soil compaction can improve field drainage and road durability.

Field Preparation: Enhancing soil structure for better crop yields.

Farm Infrastructure: Building durable farm roads and pathways.

Impact roller compactors are vital tools in various industries, offering efficient and effective soil compaction for a wide range of applications. Their ability to provide deep and uniform compaction, coupled with their versatility and environmental benefits, makes them essential for modern construction, civil engineering, mining, and agricultural projects. Understanding their purpose, usage, and benefits can help industries maximize their potential and ensure the success of their projects.

Tech

Environmental Benefits of Chopped Strand Mat

Key Benefits

As industries increasingly focus on sustainability, the environmental impact of materials used in manufacturing processes has become a critical consideration. Chopped Strand Mat (CSM) is no exception, and its environmental benefits, including recyclability and eco-friendly properties, are essential for its growing adoption in sectors such as automotive, marine, construction, and renewable energy. When compared to other traditional materials, CSM stands out for several key reasons, from its durability and lower environmental footprint during production to its potential for recycling and reuse. This article explores the environmental benefits of CSM and how it contributes to more sustainable manufacturing practices.

Recyclability of Chopped Strand Mat

One of the primary environmental advantages of Chopped Strand Mat (CSM) is its potential for recycling. While fiberglass, including CSM, is often considered difficult to recycle due to its complex composite nature, advancements in recycling technologies are making it increasingly feasible. The ability to recycle CSM not only contributes to reducing waste but also supports the growing demand for sustainable materials across various industries, including the production of cable ladder.

Cable ladder, which are widely used in electrical and communication systems to support and organize cables, can also benefit from the recyclability of CSM. Traditionally, cable ladders were made from metals like steel or aluminum, which required energy-intensive processes to manufacture and were subject to corrosion. However, with the shift toward fiberglass-based composites such as CSM, the potential for recycling these products at the end of their life cycle has increased.

- Mechanical Recycling: CSM, like other fiberglass-based products, can be processed through mechanical recycling methods. This involves breaking down the fiberglass composite into its individual components, such as glass fibers and resins, which can then be reused. Mechanical recycling of CSM typically results in the glass fibers being cleaned, repurposed, and used in the production of new composite materials, which helps reduce the need for virgin raw materials.

- Chemical Recycling: A more advanced form of recycling, chemical recycling involves breaking down the resin binder used in CSM into its chemical components, which can then be reused in the creation of new products. This process helps minimize waste and can significantly reduce the environmental impact of production, especially when the resin is derived from renewable sources.

- Circular Economy: The recyclability of CSM is in alignment with the principles of a circular economy, where materials are continuously reused, reducing the need for landfilling and conserving natural resources. As industries adopt more circular practices, the ability to recycle materials like CSM becomes an increasingly important factor in its sustainability.

Reduction in Material Waste

The manufacturing process of CSM generates minimal waste compared to many other traditional materials. The fibers used in CSM are carefully controlled during the cutting process, and excess materials can often be reused, either in the same production cycle or in the creation of other fiberglass products. This reduces the overall material waste and ensures a more efficient use of raw materials.

- Zero Waste Initiatives: Many manufacturers of fiberglass products, including CSM, have adopted zero-waste initiatives to further minimize environmental impact. This includes reusing offcuts and defective mats during the production process or sending waste materials to specialized facilities for recycling. By reducing waste at every step of the manufacturing cycle, CSM helps support environmentally responsible manufacturing.

Energy Efficiency and Reduced Carbon Footprint

The production of Chopped Strand Mat is energy-intensive but generally more efficient than the manufacturing of many other materials, particularly metals like steel or aluminum. CSM is primarily made from glass fibers, which are derived from sand and other natural resources. The energy required to produce glass fibers and process them into CSM is relatively low compared to the extraction and processing of metals, making CSM a more energy-efficient alternative in certain applications.

- Lower Embodied Carbon: The energy required to produce fiberglass products such as CSM is significantly lower than that for materials like aluminum or steel, which require high-temperature furnaces for production. This results in a lower embodied carbon, making CSM a more sustainable choice in industries focused on reducing carbon emissions.

- Durability and Longevity: CSM products are incredibly durable and resistant to environmental factors like moisture, UV radiation, and temperature changes. This long lifespan reduces the need for frequent replacements, which in turn lowers the overall carbon footprint associated with manufacturing, transportation, and disposal. For example, CSM is often used in the construction of boat hulls and automotive parts, both of which are subject to demanding conditions. The longevity of these materials means that fewer resources are consumed over time.

Non-toxic and Low Environmental Impact

Fiberglass, the core material used in Chopped Strand Mat, is non-toxic and does not release harmful substances into the environment during its manufacturing or use. Unlike some synthetic polymers and resins, which may contain harmful chemicals or release volatile organic compounds (VOCs), fiberglass is inherently safer for both human health and the environment.

- Safer for Workers: The production of fiberglass products like CSM does not involve the same hazardous chemicals that are found in many other composite materials. This reduces the risk of exposure to harmful substances for workers in the manufacturing process, contributing to a safer and more sustainable working environment.

- Low VOC Emissions: Many types of resins used in composite materials release volatile organic compounds (VOCs) during the curing process, contributing to air pollution. However, many CSM manufacturers are increasingly using low-VOC or VOC-free resins, making the production of CSM more eco-friendly. These advances reduce the environmental footprint and make the manufacturing process safer for both workers and the surrounding environment.

Lightweight Properties Leading to Reduced Energy Consumption

Chopped Strand Mat is lightweight compared to traditional building materials like metals or concrete. This characteristic has several environmental advantages, particularly in industries such as transportation and construction. For example:

- Automotive Applications: In the automotive industry, lighter materials lead to improved fuel efficiency and reduced carbon emissions. The use of CSM in vehicle manufacturing can help reduce the weight of cars, trucks, and other vehicles, ultimately contributing to lower fuel consumption and a smaller carbon footprint.

- Marine and Aerospace: Similarly, in marine and aerospace industries, the use of lightweight fiberglass materials like CSM helps reduce the energy required to propel boats and aircraft. This leads to less fuel consumption and reduced environmental impact during operation.

- Cable Ladders and Fiberglass Sheets: In both cable ladder systems and fiberglass sheets, the use of non-toxic materials ensures that no harmful emissions are released during production or usage. This is especially important in industries where worker safety and environmental health are top priorities, such as in the construction of electrical infrastructure or building facades.

Biodegradable and Natural Fiber Alternatives

While CSM itself is not biodegradable, it can be combined with natural fiber alternatives to improve its eco-friendly properties. For example, manufacturers are exploring the combination of CSM with bio-based resins or natural fibers like hemp, flax, or jute. This hybrid approach can result in products that are more biodegradable or have reduced environmental impact at the end of their lifecycle.

- Bio-composites: The development of bio-composites using natural fibers and bio-resins is an emerging trend in the CSM market. These bio-composites are designed to be more sustainable, offering a more eco-friendly alternative to traditional fiberglass composites. Such advancements contribute to a more sustainable lifecycle for CSM products.

Tech

The Growing Market for Audio Jammers

The Market Dynamics of Audio Jammers and Their Evolving Role

The market for audio jammers is experiencing steady growth due to increasing concerns about privacy, security, and surveillance. These devices, designed to disrupt unwanted audio signals, are gaining traction across a wide range of industries, including corporate, government, military, and personal privacy. As surveillance technology continues to advance, the market for audio jammers is expanding, with additional innovations such as Drone Jammer Gun and Drone RF Detection contributing to a more sophisticated approach to counter-surveillance.

Key Drivers of Market Growth

Rising Privacy Concerns

With the growing prevalence of surveillance technologies, including hidden microphones and audio-recording devices, the demand for audio jammers has increased. Individuals and organizations are increasingly concerned about unauthorized eavesdropping, particularly in environments where sensitive or confidential information is exchanged. This has driven the adoption of audio jammers in sectors such as corporate boardrooms, legal offices, and government facilities, where protecting information from external threats is paramount.

Increased Use of Surveillance Technology

The proliferation of consumer and professional surveillance devices, such as hidden microphones, drones with audio capabilities, and remote listening systems, has expanded the market for audio jammers. As more people and organizations become aware of the potential risks posed by surveillance technology, the need for countermeasures like audio jammers is rising.

Government and Defense Applications

Government agencies and defense contractors have been major adopters of audio jammers to protect against espionage and cyber-attacks. These sectors require robust security measures to safeguard sensitive information and prevent unauthorized interception of communications. Audio jammers are also used by military and intelligence agencies in the field to thwart enemy surveillance and maintain operational security.

Growing Security Concerns in Business and Personal Privacy

In addition to the government and defense sectors, businesses, especially those involved in intellectual property (IP) and confidential dealings, are adopting audio jammers to protect their trade secrets. High-profile industries, such as technology, pharmaceuticals, and finance, are increasingly concerned about information leaks, leading to greater demand for privacy-enhancing tools. In personal privacy, individuals concerned about eavesdropping, such as in their homes or personal spaces, are also contributing to market growth.

Key Applications of Audio Jammers

Corporate and Legal Sectors

In the corporate world, audio jammers are primarily used in boardrooms, meeting spaces, and executive offices where confidential discussions take place. These devices help prevent unauthorized audio recording and eavesdropping. Legal professionals, especially those handling sensitive client cases or confidential legal documents, also use audio jammers to ensure their conversations remain private and secure.

Government and Military

Government agencies and military personnel utilize audio jammers as part of their security protocol. These devices are particularly important for preventing espionage and surveillance during high-level diplomatic talks, intelligence operations, and defense missions. Audio jammers are used in embassies, government offices, and military installations to maintain confidentiality and operational security.

Personal Privacy

With the increasing concern about personal privacy, individuals are increasingly investing in audio jammers for their homes or vehicles. These devices are used to block any potential surveillance from hidden microphones or listening devices, providing individuals with peace of mind in their personal spaces. Additionally, individuals who are subject to unwanted attention, such as public figures or whistleblowers, may use audio jammers to protect their privacy.

Events and Conferences

At high-profile events, such as business conferences, product launches, or political summits, the use of audio jammers has become more common. These events often attract journalists, competitors, or other parties who may attempt to intercept sensitive discussions or gain access to proprietary information. Audio jammers are employed in such settings to safeguard against unauthorized recording and eavesdropping.

Challenges in the Audio Jammer Market

Legal and Regulatory Issues

One of the significant challenges facing the audio jammer market is the complex legal landscape. The use of audio jammers is heavily regulated in many countries, and in some places, it is outright illegal to use them, particularly in public spaces or areas with critical communications infrastructure. The risk of fines or legal penalties for using jammers in unauthorized locations can deter potential users and create barriers to market growth. The legal framework surrounding audio jammers varies widely across regions, so users must be aware of local regulations to avoid violations.

Health and Safety Concerns

Another challenge with audio jammers, especially those operating at ultrasonic frequencies, is the potential health risks they pose. Prolonged exposure to high-frequency sounds can cause discomfort or even hearing damage, particularly for sensitive individuals or animals. Some audio jammers can also interfere with medical devices, such as hearing aids or implantable devices, raising concerns about their safe usage in environments where vulnerable individuals may be present.

Technological Limitations

While audio jammers are effective in many scenarios, they are not foolproof. Advanced surveillance technologies, such as those using encrypted communications or spread-spectrum techniques, can sometimes bypass traditional jamming methods. Similarly, Drone RF Detection and Drone Jammer Gun may struggle with more sophisticated drones that use advanced communication protocols or operate at high altitudes. Continuous innovation is required to improve the effectiveness of these devices and address evolving surveillance technologies.

Consumer Awareness and Adoption

Despite the growing concern about privacy, there remains a lack of widespread awareness about audio jammers and their effectiveness. Many consumers and businesses are unaware of the options available to protect themselves from audio surveillance. Educational efforts and greater visibility of the benefits of audio jammers are necessary to accelerate adoption in both the consumer and enterprise markets.

Future Outlook for the Audio Jammer Market

The future of the audio jammer market looks promising as privacy concerns continue to grow across both personal and professional domains. As the technology behind audio jammers improves, and as more people become aware of the need to protect their conversations, the demand for these devices is expected to rise.

The integration of advanced technologies like Drone Jammer Guns and RF Detection Systems with audio jammers could further enhance their effectiveness, enabling users to protect against both physical and digital surveillance. With the increasing risk of cyber threats and data breaches, the need for robust counter-surveillance tools will likely drive further innovation in the audio jammer market.

Furthermore, as regulatory bodies adjust their stance on the use of jamming devices, more balanced and standardized regulations may emerge, which could help drive growth in the market by allowing greater usage in controlled environments.

Tech

Top Technology Trends in Accounting and Financial Services

Accounting and financial services are transforming with the rise of new technologies. Three significant trends are shaping this change. First, artificial intelligence is becoming a game changer. It streamlines processes, reduces errors, and boosts efficiency. Second, blockchain technology is gaining traction. It offers transparency and security in transactions, which is invaluable. Lastly, cloud-based solutions are making data access and collaboration easier than ever. Businesses like Padgett Business Services are leveraging these innovations to enhance their offerings. They are not alone in recognizing the potential. Many financial institutions are already integrating these technologies. This shift does not just mean quicker services. It also means more accurate and reliable outcomes. Understanding these trends is essential for staying competitive. They are not just fleeting changes. These are foundational shifts that will continue to reshape how accounting and financial services operate. Embracing them can pave the way for sustained growth and improved service delivery.

Artificial Intelligence in Accounting

Artificial intelligence (AI) is revolutionizing accounting. It automates repetitive tasks like data entry and categorization. This frees up accountants to focus on more strategic activities. AI can also analyze large volumes of data quickly. This leads to better decision-making based on accurate insights. Moreover, AI helps in detecting anomalies and potential fraud. It constantly monitors transactions and flags unusual patterns.

A simple example of AI in action is automated bookkeeping. Systems can now learn from transaction history. They predict and apply the correct account codes, reducing manual intervention. AI-powered chatbots are also common. They assist with customer inquiries, providing instant responses and improving customer satisfaction.

Blockchain Technology’s Impact

Blockchain is another vital trend. It creates a secure and transparent ledger of transactions. This is crucial for financial services, where trust and accuracy are paramount. Blockchain reduces the risk of errors and fraud. Once a transaction is recorded, it cannot be altered. This feature makes auditing simpler and more reliable.

For example, consider cross-border payments. Traditional methods can take days, but blockchain provides near-instantaneous transfers. This speed benefits both individuals and businesses. They enjoy reduced costs and improved cash flow.

According to the Federal Reserve, blockchain has the potential to improve the efficiency of payment systems. It is not yet widely adopted, but its advantages are clear. Gradually, more institutions are exploring its use in various applications beyond payments.

The Rise of Cloud-Based Solutions

Cloud computing is changing how accounting services are delivered. It offers several benefits over traditional methods. First, it allows real-time access to financial data from anywhere. This flexibility is essential in today’s fast-paced world. Second, cloud solutions enable seamless collaboration. Teams can work on the same documents simultaneously, improving efficiency.

Security is often a concern with cloud solutions. However, providers invest heavily in ensuring data protection. Features like encryption and multi-factor authentication safeguard sensitive information.

A popular application of cloud technology is accounting software. Solutions like QuickBooks Online and Xero offer cloud-based services. They eliminate the need for physical servers and regular software updates. These platforms also integrate with various apps, providing a comprehensive financial management ecosystem.

Comparison Table: Traditional vs. Modern Accounting Technologies

| Aspect | Traditional Accounting | Modern Accounting Technologies |

| Data Entry | Manual | Automated with AI |

| Data Access | Location-bound | Cloud-based, accessible from anywhere |

| Transaction Security | Centralized | Blockchain-enhanced |

| Collaboration | On-site | Online, real-time |

| Error Detection | Manual audits | AI-driven monitoring |

Future Outlook

The integration of these technologies is just the beginning. As they evolve, they will further transform the landscape. Staying informed on developments is crucial. For instance, the National Institute of Standards and Technology regularly updates its guidelines on cybersecurity, which is vital as more operations move online.

Innovation in accounting and finance is not slowing down. Technologies like machine learning and predictive analytics are on the horizon. They promise even greater advancements. Businesses that stay ahead of these trends will not only survive but thrive in this dynamic environment.

-

Home Improvement6 months ago

Home Improvement6 months agoEssential Drain Cleaning Tips for Brampton Residents

-

Fashion11 months ago

Fashion11 months agoAttractive Beach Dresses: Elevate Your Look with These Ideas

-

Entertainment10 months ago

Entertainment10 months agoNetnaija: Your One-Stop Shop for Free Movies in Africa

-

Pets10 months ago

Pets10 months agoPawsitively Perfect: The Types of Dog Harness Bundle for Your Furry Friend

-

News10 months ago

News10 months agoWhat Are the Biggest Challenges in Marine Construction Projects in Australia?

-

Health11 months ago

Health11 months agoUnderstanding Ftmç: Gender-Affirming Surgery

-

Business11 months ago

Business11 months agoHow Professional Concrete Cleaning Wins Repeat Business

-

Entertainment12 months ago

Entertainment12 months agoUnlocking Cinematic Pleasures: A Comprehensive Look at Rebahin, the Free Movie Streaming Haven