Tech

What Specs Should a Good Gaming PC Have?

It isn’t necessary that you need to have a console so that you can become a gamer, you could go for a gaming PC instead too! Now that most video game companies are also porting their games to PC, it only makes sense for you to get a gaming PC for yourself too! You can play games such as Grand Theft Auto and in June, Square Enix is also dropping the entire Kingdom Hearts series on Steam!

Not only that, you can also play online with other players from all over the world, but before you do that you need to make sure you have an internet connection that is fast and reliable enough so that you could save yourself the embarrassment of lag. In that case, you should contact Xfinity Customer Service so that they can hook you up with a brilliant internet service in a jiffy so that you can play online to your heart’s content!

In order to play on a PC, the first thing that you need to do is to get a gaming PC for yourself in the first place! However, even that requires a lot of research and you need to make sure that you have the kind of specs that would easily allow you to play all the mainstream titles that are released these days. Today we will be talking about all the specs that you need to make sure that your PC has, so try to stick to the end and read the article all the way to the end!

Your Gaming PC Needs a Strong and Fast Processor

The first thing that you need to pay attention to when you get a gaming PC for yourself is the processor. If you are getting a custom-built PC, then you have more liberty as opposed to a PC that is already built. There are two processor companies that you can choose between, you can either get an Intel processor for yourself, or you can get one by AMD.

Intel gives you processors such as the i7 or the i9 while AMD has the Ryzen series that you can get for yourself. The core count is the major consideration that you need to look into, the core count can go from two to 24 cores. However, the least that you should go for is 4 cores. The processor determines how fast your PC is going to work and whether it can support heavy games or not.

An Ample Amount of RAM for Your PC

The processor isn’t the only thing that makes your gaming PC run fast, you also need to make sure that you have a lot of RAM so that you can run hefty programs and games on your PC. This way, not only will you be able to play heavy games on your PC but you can also run heavy programs such as Adobe Photoshop and Adobe Premiere Pro on it as well.

If you are wondering about how much RAM you should get, you should get at least 16GB of RAM and if you want everything to run smoothly, then you should take it up a notch and go for 32GB of RAM instead, which will make everything smooth! So right after your processor, the next thing that you need to pay attention to is your RAM.

A Hefty Graphics Processor

We’re sure you must have always wanted to play games like Horizon Forbidden West, Spider-Man: Miles Morales, and Red Dead Redemption 2 on the highest possible graphics, right? Did you know that you can actually do that with your PC as well? All you need is a strong graphics processor (or GPU, as they call it) that is able to run games on the highest possible graphics.

To make the best out of it, you can also get a 4K monitor for yourself that comes with a 120Hz refresh rate. This would ensure that your games run at crisp quality and are as smooth as butter when you play them. While games don’t really work at 120Hz, it’s still better to get a monitor with that refresh rate to get the best output out of your gaming experience!

A Good Gaming Mouse and Keyboard

Even though this isn’t as crucial if you are someone who plays a lot of First Person Shooter (FPS) games such as Call of Duty, then this would be handy for you. You can get them with built-in RGB lights so that you can amp up your gaming vibe and make your gaming experience a lot more interesting. If you like clicky keys on your keyboard, then you should consider getting a mechanical keyboard for yourself.

Ending Note

When it comes to gaming, you shouldn’t constrict yourself to a console, you should explore your horizons and try PC gaming as well, who knows you might like it better.

Tech

Iversær – The Intricate Tapestry of Humanity

Introduction

In a world teeming with diverse cultures, unique perspectives, and varying backgrounds, the term “iversær” comes to the forefront as a beacon of unity and understanding. But what does iversær signify? How does it intertwine with the broader themes of diversity, inclusion, and human connection? This guide explores the essence of iversær, its real-world applications, and its potential to shape a vibrant and inclusive future.

Define “iversær”

Iversær is a concept that encapsulates the beauty of diversity, the richness of individual uniqueness, and the importance of fostering a sense of belonging among all people. Rooted in the idea that every person contributes to the intricate tapestry of humanity, iversær embraces differences as strengths rather than obstacles.

The Essence of Iversær

Core Values and Principles

At its core, iversær embodies values such as:

- Inclusivity: Welcoming all individuals irrespective of their backgrounds.

- Respect: Honoring the differences and unique qualities of each person.

- Empathy: Understanding and sharing the feelings of others.

- Equity: Ensuring fair treatment, opportunities, and advancement for all.

Importance of Individual Uniqueness

Every individual’s uniqueness contributes to a richer, more vibrant society. Recognizing and celebrating these differences fosters a sense of belonging and community, empowering people to bring their full selves to every aspect of life.

Contribution to Society

Iversær contributes to society by:

- Enhancing Creativity and Innovation: Diverse perspectives lead to more creative solutions and innovative ideas.

- Strengthening Communities: Inclusive communities are more cohesive, resilient, and supportive.

- Promoting Social Harmony: Understanding and empathy reduce conflicts and build stronger relationships.

Iversær in Action

Real-world Examples

- Communities: Neighborhoods that celebrate diverse cultural festivals, encouraging cross-cultural interactions.

- Organizations: Companies implementing diversity and inclusion programs that promote a diverse workforce.

- Cultures: Countries with policies supporting multiculturalism and integration.

Case Studies

- Tech Industry: Companies like Google and Apple investing in diversity initiatives, resulting in innovative products and inclusive work environments.

- Education Sector: Schools adopting inclusive curricula that reflect the diverse backgrounds of students, fostering a culture of acceptance and mutual respect.

Challenges and Opportunities

- Challenges:

- Resistance to Change

- Unconscious Bias

- Inequality and Discrimination

- Opportunities:

- Creating Inclusive Policies

- Promoting Cross-cultural Understanding

- Leveraging Technology for Inclusivity

Cultivating Iversær

Strategies for Individuals

- Self-Education: Learn about different cultures, histories, and perspectives.

- Active Listening: Listen to understand, not just to respond.

- Inclusive Behavior: Practice inclusivity in daily interactions, both personally and professionally.

Promoting Iversær in Organizations

- Inclusive Hiring Practices: Ensure diverse representation in the hiring process.

- Employee Resource Groups: Support groups that represent various demographics within the organization.

- Ongoing Training: Provide continuous education on diversity, inclusion, and equity.

Role of Education and Awareness

- Inclusive Curriculum: Integrate diverse perspectives into educational content.

- Awareness Campaigns: Run campaigns to educate the public about the importance of diversity and inclusion.

- Community Engagement: Involve communities in dialogues and activities that promote iversær.

Iversær and the Future

Shaping a Better World

The potential of iversær to shape a better world lies in its ability to bring people together, bridging gaps and fostering understanding. By championing diversity, we can create a more equitable and harmonious society.

Emerging Trends and Innovations

- AI and Inclusion: AI tools that help mitigate biases in hiring and decision-making processes.

- Global Collaboration: International partnerships focusing on global challenges through diverse perspectives.

Call to Action

Become a champion of iversær. Start by making small changes in your daily life, advocating for inclusivity in your community, and supporting policies that promote diversity and equity.

FAQs

1. What does “iversær” mean?

Iversær is a term that represents the celebration of diversity, inclusivity, and the unique qualities of each individual.

2. How can I promote iversær in my workplace?

You can promote iversær by implementing inclusive hiring practices, supporting employee resource groups, and providing ongoing training on diversity and inclusion.

3. Why is iversær important in education?

Iversær in education fosters a culture of acceptance and mutual respect, helping students appreciate diverse perspectives and build empathy.

4. What are some real-world examples of iversær?

Examples include diverse cultural festivals in communities, diversity initiatives in organizations like Google, and inclusive curricula in schools.

5. How can technology support iversær?

Technology can support iversær by providing AI tools that reduce biases, facilitating global collaboration, and offering platforms for inclusive communication.

YOU MAY ALSO LIKE

Ultimate Guide to Rssawee for Environmental and Adventure Enthusiasts

Conclusion

In summary, iversær is not just a concept but a way of life that enriches our society. By understanding its essence, witnessing its impact in action, and actively cultivating it in our lives, we can contribute to a world where everyone feels valued and included.

Tech

Harmonicode: Unveiling the Mystery of Music Through Play

Introduction

Have you ever wondered how music is created? Is there a secret code that unlocks the magic of melodies? If these questions pique your curiosity, you’re in for a treat! Enter Harmonicode, a revolutionary product that makes learning music theory fun and engaging for all ages. Whether you’re an environmental enthusiast, an adventure lover, or a small business owner, Harmonicode has something to offer.

What is Harmonicode?

Category and Price

Harmonicode belongs to the Games category and is currently priced at US$120.00. The good news? It’s in stock and ready to bring a world of musical discovery right to your doorstep.

Functionality

Harmonicode is designed to teach music theory concepts in a playful and interactive way. It’s both a physical and digital product, offering a unique blend of tactile and online learning experiences. It transforms what can often be a dry subject into a fun, engaging activity.

Target Audience

Harmonicode is perfect for:

- Aspiring musicians of all ages

- Individuals who want to understand the building blocks of music

- Teachers looking for innovative ways to engage students

- Families wanting to learn together

How Does Harmonicode Work?

Gameplay/Usage

Harmonicode can be used as a game, a puzzle, or a musical instrument simulation. Here’s how to get started:

- Unbox Your Harmonicode Kit: Inside, you’ll find a set of beautifully designed cards and access to the Harmonicode digital platform.

- Setup: Follow the instructions to set up your physical or virtual game space.

- Begin Playing:

- Music Theory Fundamentals: Learn scales, chords, and intervals through interactive challenges.

- Interactive Gameplay: Engage with puzzles that require you to apply music theory concepts to progress.

- Track Progress: Use the built-in progress tracker to monitor your learning.

Key Features

Harmonicode stands out because of its unique features:

- Teaches Music Theory Fundamentals: Covers scales, chords, intervals, and more.

- Interactive and Engaging Gameplay: Keeps users motivated and eager to learn.

- Suitable for Various Skill Levels: Whether you’re a beginner or more advanced, Harmonicode adapts to your level.

- Additional Features:

- Progress tracking

- Challenges and rewards

- Community interaction

Benefits of Using Harmonicode

Enhanced Musical Understanding

- Strong Foundation: Develop a solid understanding of music theory.

- Skill Improvement: Improve your composition and performance skills.

- Deeper Appreciation: Unlock a deeper appreciation for music by understanding its building blocks.

Fun and Engaging Learning

- Less Intimidating: Makes learning music theory less daunting and more fun.

- Motivational: Interactive gameplay keeps you engaged and motivated.

- Family Activity: Suitable for all ages, making it a great family activity.

Social Proof and Credibility

User Testimonials

Don’t just take our word for it—here’s what some of our satisfied users have to say:

- Steve, USA: “I can’t believe that Harmonicode is free! It’s ideal for making sure all of my work is polished and professional.”

- Penny, Australia: “I use this product almost every day! The complex rephrasing component complements grammar products like Grammarly and LanguageTool really well. Great job!”

Awards and Recognition

Harmonicode has received several industry awards for its innovative approach to music education, reinforcing its credibility and effectiveness.

FAQs

- What is Harmonicode?

- Harmonicode is an interactive product designed to teach music theory concepts in a fun and engaging way, suitable for all ages and skill levels.

- How much does Harmonicode cost?

- Harmonicode is priced at US$120.00 and is available in stock, ready to bring musical discovery to your doorstep.

- Who is the target audience for Harmonicode?

- Harmonicode is perfect for aspiring musicians, individuals wanting to learn music theory, teachers, and families looking for a fun, educational activity.

- What features does Harmonicode offer?

- Harmonicode offers music theory fundamentals, interactive gameplay, progress tracking, challenges, rewards, and community interaction.

- How does Harmonicode enhance musical understanding?

- By providing a strong foundation in music theory, improving composition and performance skills, and fostering a deeper appreciation for music.

YOU MAY ALSO LIKE

Engaging Dental Websites: Best Practices for Attracting and Retaining Patients

Conclusion

Recap the Value Proposition

Harmonicode is not just a tool; it’s a gateway to unlocking the mysteries of music theory through play. With its interactive gameplay, comprehensive learning modules, and suitability for all ages, it’s the perfect addition to any music enthusiast’s toolkit.

Tech

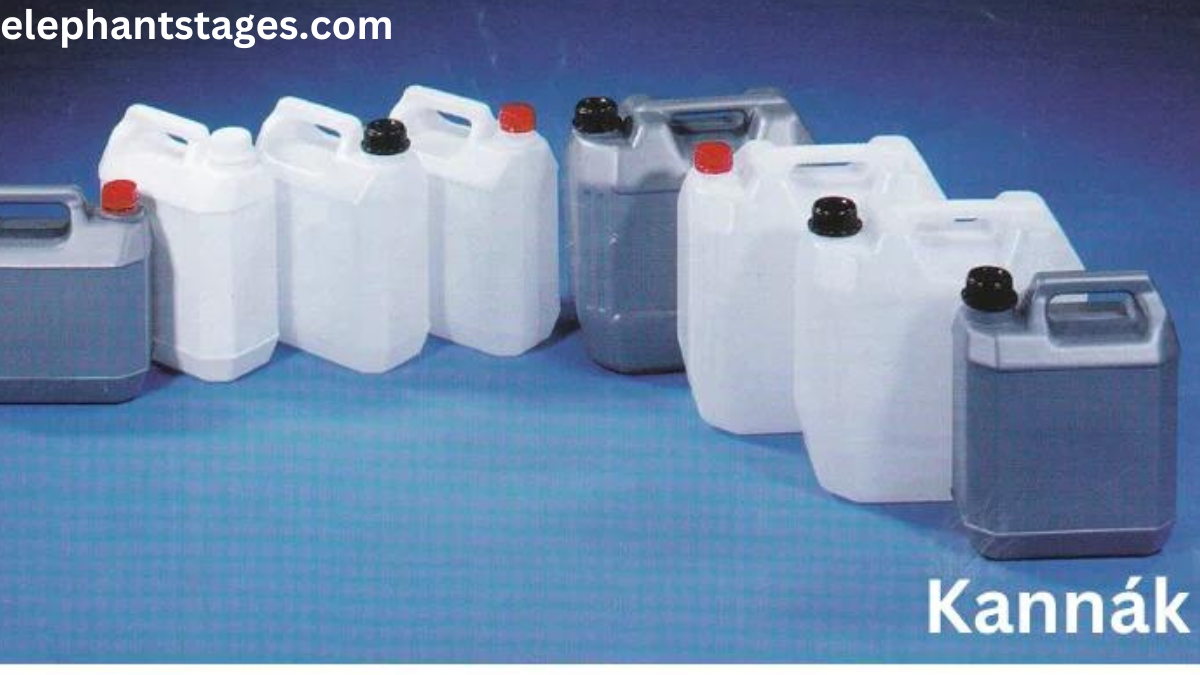

Kannák – The Epitome of Strength and Functionality

Introduction

Imagine a world where every tool, every piece of equipment, and every resource you use embodies the perfect balance of strength and functionality. What if there were a term that encapsulated this ideal? Enter Kannák.

What is Kannák?

Kannák, pronounced “kan-ak,” stands as a testament to the fusion of power and utility. Though the term may be unfamiliar to some, its implications are universally relevant. Kannák represents not just physical robustness, but also the relentless efficiency and effectiveness needed to overcome challenges and achieve success.

The Essence of Kannák

Strength

Physical Attributes

- Durability: Kannák is built to last. Whether it’s withstanding the harshest weather conditions or enduring rigorous use, Kannák remains unyielding.

- Resilience: Beyond mere durability, Kannák can bounce back from setbacks, maintaining its integrity and functionality.

- Resistance: Kannák is designed to resist wear and tear, corrosion, and other forms of degradation.

Metaphorical Strength

- Symbol of Power: Kannák isn’t just about physical strength. It symbolizes the power to push through obstacles and achieve greatness.

- Courage: Embodying Kannák means having the bravery to face challenges head-on.

- Determination: With Kannák, there’s an unwavering commitment to reach goals, no matter the difficulty.

Functionality

Practical Applications

- Versatility: Kannák can be used in various contexts, from everyday tools to specialized equipment.

- Efficiency and Effectiveness:

- Optimal Performance: Kannák delivers results with minimal effort and maximum impact.

- User-Friendly: Even the most complex versions of Kannák are designed for ease of use.

Kannák in Various Domains

Kannák in Adventure Gear

For adventure enthusiasts, Kannák could be the defining trait of their gear.

- Backpacks:

- Strength: Reinforced stitching, durable materials.

- Functionality: Multiple compartments, ergonomic design.

- Tents:

- Strength: Weather-resistant fabrics, sturdy poles.

- Functionality: Easy setup, compact storage.

Kannák in Small Business Tools

Small business owners often seek tools that exemplify Kannák.

- Software Solutions:

- Strength: Robust security features.

- Functionality: Intuitive interfaces, comprehensive analytics.

- Marketing Tools:

- Strength: Reliable servers, high uptime.

- Functionality: Customizable templates, user-friendly dashboards.

Kannák and Related Concepts

Comparisons

How Kannák differs from similar terms/products:

- Quality vs. Quantity:

- Kannák focuses on excellence, ensuring each product or resource is of the highest quality, whereas quantity-focused options may prioritize volume over value.

Complementary Elements

What enhances the capabilities of Kannák:

- Technological Integrations:

- Smart Features: IoT (Internet of Things) can enhance Kannák products, providing real-time updates and remote control capabilities.

- Sustainable Practices:

- Eco-Friendly Materials: Using materials that are both strong and environmentally friendly enhances the overall value of Kannák.

The Future of Kannák

Innovations

- Advanced Materials:

- Nanotechnology can further enhance the strength and durability of Kannák products.

- AI Integration:

- Predictive Maintenance: AI can predict when a Kannák product needs servicing, ensuring it remains functional for longer.

Trends

How Kannák aligns with current or future trends:

- Sustainability:

- Eco-conscious consumers are increasingly demanding products that are not only strong and functional but also environmentally responsible.

- Customization:

- Personalized Solutions: The future of Kannák includes bespoke products tailored to individual needs and preferences.

Five Most Searched FAQs on Google and Answers

- What does Kannák mean?

- Kannák symbolizes the perfect balance of strength and functionality, combining physical robustness with relentless efficiency.

- How is Kannák applied in adventure gear?

- In adventure gear, Kannák is embodied through features like reinforced stitching in backpacks and weather-resistant fabrics in tents.

- Why is Kannák important for small business tools?

- Small business tools with Kannák offer robust security and user-friendly interfaces, ensuring reliability and efficiency.

- What innovations enhance Kannák products?

- Innovations like nanotechnology and AI integration enhance the strength, durability, and predictive maintenance of Kannák products.

- How is Kannák related to sustainability?

- Kannák aligns with eco-conscious trends by using strong, environmentally friendly materials, catering to the growing demand for sustainable products.

YOU MAY ALSO LIKE

Why RAID Remains a Preferred Choice for Modern Data Centers

Conclusion

Kannák stands as a beacon of strength and functionality, applicable across various domains and essential for overcoming life’s challenges. From adventure gear to small business tools, Kannák ensures optimal performance and durability. As we look to the future, innovations in material science and technology will only enhance Kannák’s relevance and impact.

-

News3 months ago

News3 months agoWhat Are the Biggest Challenges in Marine Construction Projects in Australia?

-

Health4 months ago

Health4 months agoUnderstanding Ftmç: Gender-Affirming Surgery

-

Fashion3 months ago

Fashion3 months agoAttractive Beach Dresses: Elevate Your Look with These Ideas

-

Tech3 months ago

Tech3 months agoAiyifan: Unveiling the Genie of Technological Revolution

-

Business3 months ago

Business3 months agoHow Professional Concrete Cleaning Wins Repeat Business

-

Tech4 months ago

Tech4 months agoThe Ultimate Guide to the Geekzilla Podcast: Diving into the Heart of Geekdom

-

Pets2 months ago

Pets2 months agoPawsitively Perfect: The Types of Dog Harness Bundle for Your Furry Friend

-

Health3 months ago

Health3 months agoDesk Job Dilemma: Tips for Back Pain Relief